Ladders are a common tool for accessing work at heights. They are quick and easy to use and there always seems to be one around.

However, the truth is that, although we have been using ladders for thousands of years, they are actually one of the more dangerous means of accessing work at heights.

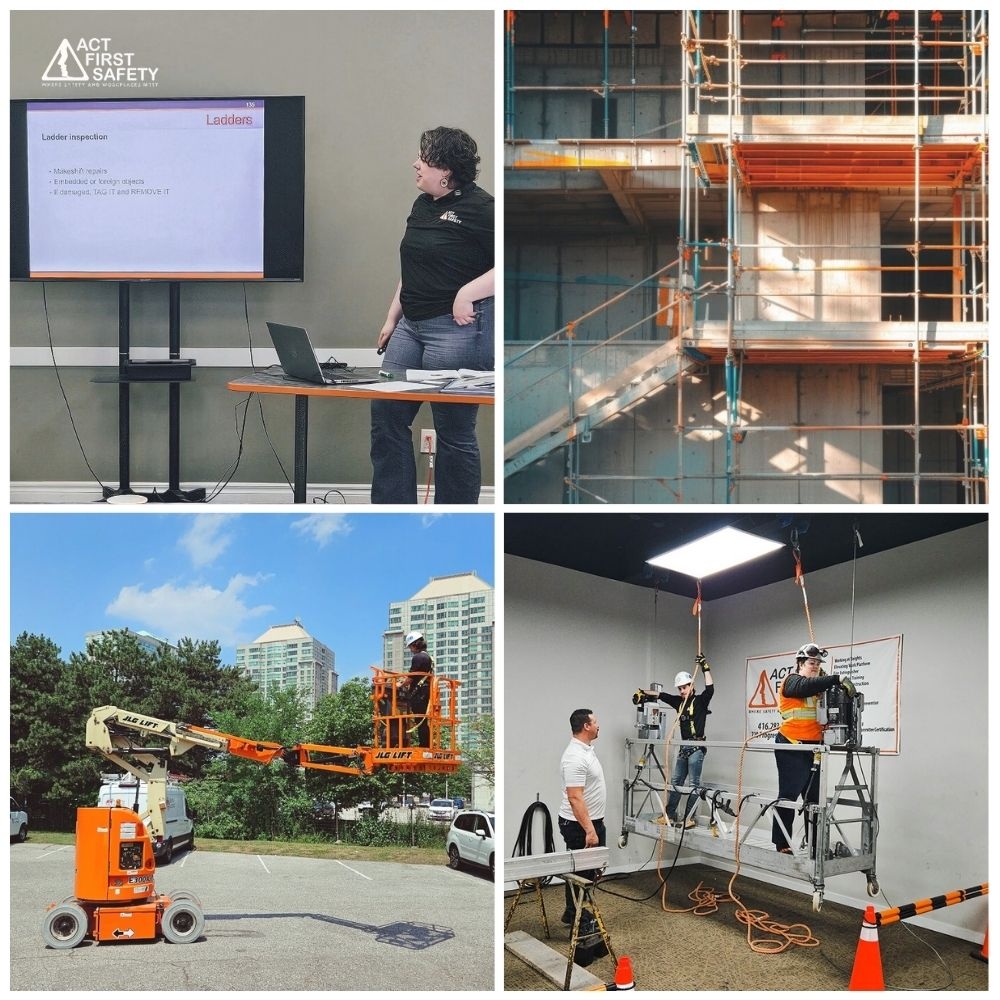

Making up almost a quarter of fatal falls in Ontario workplaces, it is clear that ladders should be avoided when possible – especially in situations where they do not provide safe access. Thankfully, there are many alternative methods to access work at heights, such as scaffolding, MEWPs, and more.

In today’s blog, Act First Safety – a trusted provider of safety training courses in Ontario, will explain when each of these ladder alternatives should be used. Let’s begin!

Scaffolding: Safety You Can Stand On

Scaffolding may be as old as the ladder itself, but its flexibility sets it apart. The fact that it can be installed anywhere while achieving a height several stories high, scaffolding has earned its reputation as one of the safest and most reliable access solutions available.

In fact, scaffolding as a method for elevated work is also recognized by Ontario regulatory standards. Covered by the construction regulations O.Reg 213/91 under sections 126 to 136.O.1, these specify the general requirements and height limits for scaffolding.

As per these regulations, scaffolding must be installed by a competent person only or under the direction of a competent person within a certain height limit. If this limit is crossed, the scaffolding must be designed by an engineer. These limits are based on the type of scaffolding being erected:

- Frame scaffold: 15 metres (49 feet)

- Tube and clamp scaffold: 10 metres (32 feet)

That said, the person employed to install scaffolding must have received prior competent supervisor training to qualify.

Engineered scaffolding structures should be built to meet the requirements of the latest version of the standards CSA S269.2 Access scaffolding for construction purposes and CAN/CSA – Z797 Code of practice for access scaffold.

While it is possible to build massive scaffolding structures under the guidance of an engineer, they are rare. This is mainly due to the immense labor and material costs required to build such structures. However, they make a lot of sense for large, extensive projects that will last many months or years.

Suspended Work Platform Systems (SWPS): Access from the Top Down

Suspended work platform systems come in various types and configurations – from one-person bosun’s chairs (boatswain’s chairs) to large multipoint suspended work platform systems. While there are many variations of this type of access, they have one thing in common.

Coincidentally, that commonality is the biggest factor in determining if a SWPS would be a good choice to access the work area. Basically, what they all have in common is the method used to suspend them. You must have access to the top of the structure to install the SWPS, as it is suspended from the structure.

Only those who are trained to meet the requirements of O.Reg 213/91 sections 138 can use a SWPS, while those who are installing the equipment require additional training as stated in section 138.1.

When the SWPS is a multipoint suspended platform, the constructor (the person or company in charge of the project) must notify the Ministry of Labour (MLITSD) 48 hours in advance before the platform is put into service for the first time. Additionally, a notice stating its use must be posted in a visible location at the workplace.

All SWPS must meet the requirements of the CSA standard Z271-10 Safety code for suspended platforms. Moreover, site-specific drawings must be made for the SWPS by an engineer if any of the following apply:

- Presence of stacked or tiered work platforms onsite

- Use of work platforms that weigh more than 525 kilograms, including their components

- Work platforms that span greater than 12 metres between adjacent points of suspension

- Work platforms that have more than two primary suspension lines

- Use of more than two hoisting devices to move a work platform

- Work platforms that have any shielding, tarpaulin, enclosure, sign or banner on them that may increase the wind loads on the components of the suspended system

- Exceeding the vertical distance between the top of a suspension line and the lowest point on the street, ground, or other horizontal surface under a work platform by 150 meters as per O. Reg. 242/16, s. 11.

Typically, SWPS are small, and therefore, generic drawings provided by the manufacturer are followed when installing the platform.

For many jobs, SWPS are the only practical way to gain access to the work area, which is why they are the go-to option for work on high-rise structures. That said, swing stage training is strongly recommended for their set-up and use on any site.

Mobile Elevating Work Platforms (MEWP): Reach More, Move Faster

While both scaffolding and SPWS platforms must be assembled and disassembled on site, mobile elevating work platforms (MEWP) can be repositioned without having to dismantle the equipment.

Available in different sizes and reach capabilities, they are a popular choice for construction and maintenance jobs.

As for regulatory requirements for their use, these can be found in sections 143 to 149 of the construction regulations. As per these regulations, MEWPs must be engineered following industry-wide best practices to ensure they meet the requirements of CSA standards found in the B354 series and C225 series in the case of vehicle-mounted aerial devices.

Currently in Canada, there are many suppliers of CSA-approved MEWPs that have large catalogues of available equipment for sale and for rent. With so many options to choose from, it is critical that you select equipment that accounts for the environment the MEWP will be operated in and what reach capability is needed.

One often overlooked factor in the selection of MEWPs is the weight and size of the machine, which can lead to the selection of the wrong machine to accomplish specific tasks.

MEWPs like scissor lifts and boom lifts, for example, are very heavy for their size. They need a stable surface to counterbalance their weight. Since the majority of their weight is concentrated in a relatively small area, it can be hazardous when work surfaces aren’t rated to support such a heavy load.

In fact, there have been multiple incidents where a MEWP has caused structural collapse of the surface on which it is operating. That is why it is critical for employers to ensure that surfaces in the workplace are capable of supporting any load that may be applied to them under the legislation. Surveying the ground for hidden voids and covered vaults while assessing its load-bearing capacity is crucial to preventing these incidents.

Also, using trained operators certified in aerial lift training can also help minimize onsite accidents.

Training: A Necessary Step For The Use of Ladder Alternatives

While the use of any vertical access equipment requires training, the most critical of them is working at heights training. This is a prerequisite for the use of any of the equipment explored in this article.

Additionally, depending on the type of access solution chosen, specific equipment training must be conducted, such as scissor lift training, swing stage training, and scaffold training.

However, if circumstances force you to use a ladder, remember that it requires training too – specifically ladder safety training. All in all, worksite-specific training should always be a part of a good safety plan.

Conclusion

Safe alternatives to ladders for working at heights exist, and they each bring their own strengths and weaknesses. Proper planning is critical in determining which of these options is the safest and most practical choice for the job.

Scaffolding, suspended work platform systems, and mobile elevating work platforms are all sound choices, provided you have trained workers setting up and using this equipment. Act First Safety provides high-quality working at height, MEWPs training, and SWPS training in Ontario. Our strategically located facility off HWY 401 is easily accessible and home to multiple training programs, which can be availed of in a course of a day or two. Contact us to know more.

FAQs

When is a ladder acceptable for working at heights in Ontario?

A ladder is a good choice for tasks of shorter durations that typically involve light work and when the use of other vertical access solutions is not feasible.

Can workers receive training for the use of multiple types of height access equipment?

Yes! However, each course must be taken separately and completed successfully. The worker must have a valid certification that clearly states their competency to use each type of equipment.

What are the common causes of accidents involving ladder alternatives?

Though safer, ladder alternatives can also pose a risk of accidents if they are not properly set up, ground conditions are unstable, and if environmental conditions are not conducive for operation.