Elevating work platforms are known by a variety of names, both official and informal, depending on their design and function. Understanding the jargon is crucial for safety and productivity in the access industry and in ensuring that the correct safety training on the equipment to be used is received. For example, you might need boom lift training if you work with them.

That said, the official terminology has evolved over the years, with the American National Standards Institute (ANSI) now classifying these machines as Mobile Elevating Work Platforms (MEWPs), which is also the most widely used term. However, you'll still commonly hear a variety of other names, including:

- Aerial Work Platforms (AWP)

- Aerial Lifts

- Elevating Work Platforms (EWP)

- Boom Lifts and Articulating Booms

- Cherry Pickers: Originally referred to as boom lifts for picking fruit

- Buckets or Vehicle-mount aerial devices

- Man-Lifts or Personnel Lifts: Used to describe MEWPs that are specifically designed to lift one or two people and are often smaller and more portable.

Furthermore, definitions adapted from the CSA standards referenced in the Ontario Construction Regulations include:

Elevating Rolling Work Platform: Any non-self-propelled machine that can be moved to overhead working areas.

Self-Propelled Elevating Work Platform: Any work platform, other than an articulating or telescoping boom-supported platform or a vehicle-mounted aerial device, that can be self-elevated to overhead work locations, and can be power-propelled with the help of its main controls. Scissor lifts are a leading example. Bear in mind, operating one demands scissor lift certification.

Boom-type elevating work platform: A self-propelled machine consisting of a boom-supported platform that may be telescoping, articulating, rotating, or extending beyond the base dimensions. This excludes a vehicle-mounted aerial device.

Vehicle-mounted aerial device: Any elevator that is mounted on a carrier vehicle that is manufactured separately from the platform and is designed to be driven on public thoroughfares.

So what seems like a long list of terms can confuse. A wave of the hand can seemingly leave the impression of indifference or that all equipment used is alike. Complacency can easily set in.

Of course, knowing exactly the equipment that is to be operated is important. It impacts the type of safety training received and more. You cannot simply take working at heights training and hope that it will help you operate a lift too. Coordinators, safety professionals, and individuals need to understand exactly the type of equipment operated so that the proper safety training and safety instruction are received to keep everyone safe on the job.

Key Types of MEWPs

The different MEWP names often correspond to a specific machine type or its function. The two most basic types of MEWPs are defined by their lifting mechanism:

- Scissor Lifts: Characterized by their crisscross, accordion-like "scissor" mechanism that extends vertically to lift the platform. They are ideal for jobs that require a large work area with direct vertical access.

- Boom Lifts: These use a hydraulic-powered arm, or "boom," to lift the platform. They are designed for jobs that require horizontal reach over obstacles. Boom lifts are further categorized by their boom type:

- Articulating Boom Lifts: Also known as "knuckle booms" or "Z-booms," these have multiple hinged sections, allowing the operator to maneuver the platform up, over, and around obstacles.

- Telescopic Boom Lifts: Alternatively called "straight booms," these have a single, straight arm that extends and retracts like a telescope, offering maximum horizontal and vertical reach.

Essential Components and Terminology

Beyond the main types, a comprehensive vocabulary is key to understanding and operating MEWPs safely. Here are a few must-know terms:

- Platform (or Basket): The enclosed workspace where the operator stands. It includes the guardrails for safety and the control panel for operation.

- Chassis (or Base): The foundation of the machine. It houses the engine, axles, and wheels or tracks, providing stability and mobility.

- Turntable: Located at the base of a boom lift, this allows the boom arm to rotate horizontally, often a full 360 degrees.

- Outriggers (or Stabilizers): Extendable devices that increase the machine's footprint to provide extra stability, especially on uneven terrain.

- Jib: An extra articulated arm at the end of the main boom, which provides additional range of motion and precision for the platform.

- Working Envelope: The entire area that a boom lift's platform can reach, including its maximum height and outreach.

- Working Height: The maximum platform height plus a standard allowance (usually 6 feet or 1.8 meters) to account for an operator's overhead reach. This is often different from the machine's “platform height.”

- Gradeability: The ability of the machine to climb a slope, that is represented as a percentage.

- Oscillating Axle: An axle designed to pivot, allowing all wheels to remain in contact with uneven ground for better traction and stability.

Understanding the specific type of Mobile Elevating Work Platform (MEWP) is critically important for several reasons, primarily concerning safety, job efficiency, and regulatory compliance.

Here’s a detailed breakdown of why this knowledge is essential:

- Safety: The most crucial reason is accident prevention. Each MEWP type is designed for a specific task and environment.

- Knowing a MEWP’s limitations prevents you from using it on unsuitable terrain, such as using an indoor-only scissor lift on uneven ground, which could lead to a tip-over.

- Understanding the controls and functions of a specific model, like an articulating boom lift, is vital to avoid striking objects or electrocution from power lines. Without proper aerial lift training on the correct MEWP type, an operator is a serious risk to themselves and others.

- Performing equipment inspections and knowing what to be looking for based on the equipment type, make, and model is critically important for maintaining and operating a MEWP safely.

- Job-Site Efficiency: Selecting the right MEWP for the job is a major time and money saver. For instance,

- A simple task requiring a large workspace at a modest height, a scissor lift provides a steady, spacious platform.

- For a job that requires reaching up and over an obstacle, an articulating boom lift is the only logical choice. Using a scissor lift for a task that requires horizontal reach would be impossible and inefficient.

- For maximum vertical and horizontal reach in a single, unobstructed line, a telescopic boom lift is the most effective tool.

- Regulatory Compliance and Certification: CSA standards, ANSI standards, and OHSA are very clear about the need for proper training and certification.

- CSA standards classify MEWPs into different groups and types (e.g., Group A for vertical lifts, Group B for boom lifts), each with specific design and safety requirements.

- A variety of sources, such as regulations, labour directives, industry-specific guidelines, and corporate policies, draw on the indications that only trained and authorized personnel can operate MEWPs. Aerial lift training should center around the type of MEWP. Operating a machine without the correct certification on the type of equipment being operated can result in fines and legal liability for both the operator and the company.

It should be noted that because of the specificity of training on specific equipment and because of the dynamic range of equipment types, online learning would only be able to provide generic or low-level awareness of MEWPs. In addition, properly conducted MEWP training would also include practical instruction on the specific equipment type being used. Of course, since MEWPs have operators performing work at heights, a working at heights certification is required prior to MEWP training.

Conclusion

In summary, clearly understanding the terminology used in reference to the equipment to be operated is critically important and impacts what happens next. To put it more concisely, a clear grasp of terminology is the essential prerequisite for:

- Safety & Training: Ensuring a common language for proper instruction and hazard communication.

- Performance & Compliance: Guaranteeing the right equipment is chosen and operated correctly according to industry standards.

- Maintenance: Facilitating accurate communication for troubleshooting and upkeep, which ensures the equipment's longevity and reliability.

So, the next time you think that vocabulary is just for elementary school, remember when it comes to safety and specifically safety training, using accurate language goes beyond the A, B, and Cs. Using the correct language and equipment terminology is a foundational requirement that directly influences every critical aspect of MEWP use.

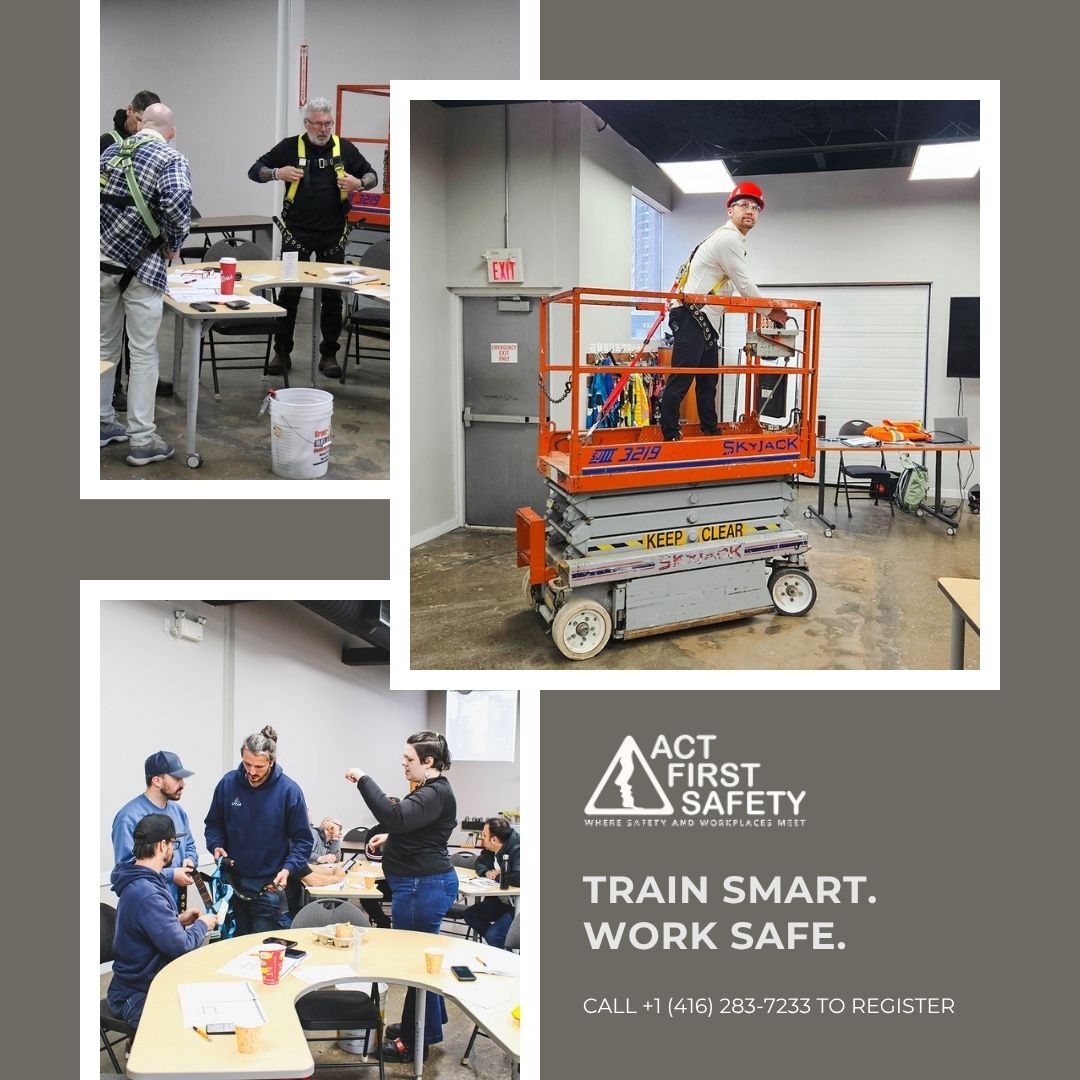

If you want to safeguard your team against potential workplace accidents and improve operator performance, you must enroll in Act First Safety’s aerial lift training program in Scarborough. Expert-led, our compact yet detail-oriented course only takes a single workday to complete. Contact us to register for our fully compliant program that comes with a valid and widely recognized certificate.